Share this

What is Fashion Product Lifecycle Management (PLM)?

by Surefront on Jun 4, 2024 1:00:00 PM

Home > Blog > What is Fashion PLM?

Table of Contents

- Improving internal and external collaboration

- Unique challenges for fashion PLMs

- How fashion PLMs increase speed-to-market

- The 4 phases of fashion PLM

- PLM needs of different fashion segments

- Example of a PLM boosting a fashion brand

- Best PLM tools for fashion brands

- The power of Surefront's fashion platform

Fashion and apparel industry leaders are always looking for disruptive technologies to accelerate product development. It’s a difficult ask because product development is iterative and takes the effort of many people and departments.

The need for internal and external collaboration

Businesses wanting to accelerate product development need a tool that organizes, stores, and leverages information about each product. This tool needs to facilitate collaboration between both internal and external stakeholders.

That’s where Product Lifecycle Management (PLM) comes in. A PLM helps lock down an A-Z process for creating orders and tracking each development step. Your apparel PLM software should be a data-driven tool for making informed decisions about new products and product lines.

Here’s everything you need to know to find a fashion-optimized solution.

What makes the fashion industry a unique PLM challenge?

Fashion is all about staying ahead of trends and meeting consumer demands. The quicker and more efficient your development process, the sooner you can get from runway to market.

Fashion product development demands a finely tuned process that can handle rapid changes in style and seasonality. Fashion leaders want to be able to spot trends and convert them into products on shelves as quickly as possible—outpacing competitors.

The biggest problem with this goal is efficiently collaborating with external teams. A fashion company has only so much influence and control over external teams. That’s why it’s crucial to consider how a PLM solution can break internal efficiency barriers and address collaboration weaknesses.

How Does Fashion PLM Increase Speed to Market?

A fashion PLM helps you bring products to market and aims to organize the information, actions, and personnel across the product lifecycle. A PLM optimizes everything from ideation and sourcing to production and distribution.

Product Lifecycle Management originated in the automobile and aviation industries, where complex manufacturing processes involve sourcing millions of components from thousands of suppliers. Fashion companies took cues from this industry and developed a PLM system for apparel that tracks all inputs for a product.

With this level of detailed organization and management, fashion PLM drives improvement across these 3 critical areas:

- Product Cost

- Product Quality

- Time to Market

Cutting product costs

Cutting down product development costs is a balancing act. You want to deliver a high-quality product while minding the time and resources required for each step along the fashion value chain. Each input has a cost based on the materials, programs, and paid personnel involved.

Streamlining your process with a fashion PLM system drives down your production costs. It does this by centralizing the product collaboration process on a single system—giving you unparalleled supply chain transparency.

Improving product quality

Refining your PLM process over time and product lines improves product quality. Important points to consider when assessing the quality of your potential apparel manufacturing PLM are:

- Striking the right balance between efficient sourcing and material quality

- Establishing a design iteration process that leverages data from past products

- Building a feedback process that includes only key stakeholders

Accelerating time to market

Improving your time to market is all about maximizing efficiency by eliminating waste. You can tweak or cut out unnecessary or redundant steps as you track the process. This helps better define your employees’ roles within the lifecycle and results in a streamlined workflow.

Quicker time to market means a faster production process, more items per season, and more opportunities to sell higher volume.

If you want to learn more about PLM apparel systems, read on about the 4 phases and best tools. If you want to explore more methods for merchandising improvement, check out our blog on category management.

The 4 Phases of Product Lifecycle Management (PLM)

Tracking and monitoring the end-to-end product process is key to implementing a successful management system. To start, you can think of the lifecycle in 4 general phases.

1. Concept

The lifecycle begins with inspiration, driven by consumer needs, market research, and trend analysis. Designers and product managers work together to conceptualize new products that align with brand identity and market demands.

This phase involves:

- Brainstorming

- Sketching

- Initial design proposals

Fashion PLM systems like Surefront help track these ideas, providing a centralized platform for collaboration and feedback.

2. Design

Once the concept is solidified, the next step is transforming ideas into tangible designs. This phase includes:

- Detailed sketches

- Technical drawings

- Creation of prototypes

Collaboration is key, with designers, product managers, and third-party vendors working together. PLM systems facilitate this collaboration by storing design files, feedback, and revisions in one accessible location.

Tools like 3D viewers and image markup allow teams to visualize designs and make necessary adjustments efficiently.

Surefront stands out as the only system on the market that offers tools like image markup and product collaboration in a shared space—accessible to internal and external partners. Best of all, you get to decide on the level of access any given partner has to the system.

3. Production

With the design finalized, the focus shifts to manufacturing. This phase involves:

- Sourcing materials

- Managing production schedules

- Overseeing the creation of the final product

PLM systems can track the whole process:

- Materials

- Labor costs

- Production timelines

- Quality control measures

This ensures that production runs smoothly and that any issues are quickly addressed.

Efficient PLM systems help manage large SKU counts and ensure accurate tracking of sizes, colors, and runs (matrix items)—which is particularly important in fashion.

4. Distribution and Maintenance

The final phase involves the distribution of products to sales channels. Logistics managers need accurate data on:

- Production quantities

- Shipping schedules

- Warehouse space requirements

PLM systems can assist in tracking orders as they move from supplier to warehouse.

Customer support teams also play a role in this phase, using PLM data to address post-sale issues and gather feedback for future improvements.

.jpg?width=745&name=FashionPLM_Infographic_02%20(1).jpg)

Segment-Specific Needs in Fashion PLM

Different segments within the fashion industry have unique requirements and challenges. Here’s how PLM systems cater to these specific needs:

Fashion Retailers

Department stores like Macy’s, Nordstrom, Penney’s, and Kohl’s primarily purchase branded fashion (about 80% of their inventory) and develop white/black label products for the remaining 20%.

They rely on PLM systems to develop white/black label products efficiently. They may also use the PLM to collaborate with brands over purchase orders and potential products.

Off-Price Retailers

Off-price retailers such as TJ Maxx, Marshalls, Ross, and Burlington sell after-season multi-brand inventory at lower prices. These retailers are typically not involved in designing and bringing products to market, so they have less use for a PLM system.

Vertically Integrated Fashion Brands

Brands like Abercrombie, AEO, Gap, J Crew, and Victoria’s Secret manage the entire supply chain from design to production to sales.

These brands often operate through franchise partners. They are essentially wholesalers to franchisees, so they need robust PLM systems to support wholesale operations and ensure consistent product quality across all outlets.

These brands would use Surefront’s Wholesale CRM to manage franchisee relationships while using Surefront’s PLM to manage product collaboration with suppliers.

Fast Fashion Brands

Fast fashion brands such as Zara, H&M, Forever 21, and Guess focus on rapid design and production cycles to accelerate runway trends to market.

PLM systems in this segment are crucial for managing a high volume of data, touchpoints, and tasks associated with fast fashion. A solid fashion PLM automates and simplifies each step of the development process so that on-trend products get to stores swiftly—with many sizes, colors, and styles.

Efficient management of matrix-type items (size, color, run) and smart tools like BOM (Bill of Materials) are critical in this fast-paced environment.

Practical Example of How a PLM System Benefits Fashion Brands

Let's illustrate how a PLM system can streamline processes for a fashion retail segment, such as department stores or vertically integrated brands.

Phase 1: Concept Development

Scenario: You are a clothing brand looking into winter trends for the season.

Team Involved: Designers, Design Assistants, Creative Director, Product Managers

Process:

- Track industry trends, analyze seasonal consumer behavior, and gather examples from influencers.

- Decide on a new product, such as wide-leg trousers.

- Store and organize all inspiration data, trend analyses, and initial concepts in the PLM system.

A PLM system efficiently manages early-stage inspiration and data. It centralizes all data, making it easy to access and analyze trend reports, past sales data, and visual inspirations. It keeps everyone on the creative team up-to-date, enabling cohesive decision-making and idea development.

Phase 2: Design and Prototyping

Team Involved: Designers, Design Assistants, Creative Director, Product Managers, Quality Assurance, Third-Party Buyers, Third-Party Vendors

Process:

- Create initial sketches and technical drawings of the wide-leg trousers

- Gather feedback from key stakeholders and iterate designs

- Collaborate with retail buyers and textile vendors for material selection

- Store feedback and design changes in the PLM system for future reference

The PLM system seamlessly integrates design tools and collaboration throughout this stage. Designers can upload sketches and technical drawings directly into the PLM system, where stakeholders can review and provide feedback.

Collaboration features enable real-time communication with external partners like textile vendors, streamlining material selection and procurement.

Phase 3: Production

Team Involved: Designers, Design Assistants, Creative Director, Product Managers, Sourcing, Quality Assurance, Accounting, Third-Party Manufacturing Reps

Process:

- Translate final wide-leg trouser designs into tech packs with all necessary details

- Send tech packs to manufacturers or collaborate directly through the PLM system

- Track material and labor costs, schedule production, and ensure quality

Your PLM should provide templates and tools to create comprehensive tech packs. These tech packs should include measurements, materials, colors, and other specifications.

With Surefront, these packs can be shared directly with manufacturers through the system, ensuring clarity and reducing the risk of errors. Additionally, our PLM system can track costs and production schedules, providing transparency and enabling proactive management.

Phase 4: Distribution and Sales

Team Involved: Logistics Manager, Warehouse Manager, Warehouse Team, Product Manager, Sales Reps, Accounting, Third-Party Buyers, Third-Party Accounting

Process:

- Receive finished products and manage inventory.

- Organize, store, and assign SKU numbers for shipping to sales channels.

- Track sales performance and gather data on consumer preferences.

The PLM system tracks the progress of items as they are manufactured and shipped. This ensures that warehouse teams have precise information about the arrival of new products. Additionally, the system can analyze sales data to identify trends and preferences, aiding in future product planning.

Final thoughts

This example illustrates the critical role a PLM system plays in streamlining processes, enhancing collaboration, and improving product quality while reducing time to market and costs. A robust PLM system is essential for staying competitive and successful in the fast-paced fashion industry.

Product Lifecycle Management (PLM) Tools for Fashion Brands

At this point, you’re probably wondering what tools you can use to implement and maintain fashion PLM systems. Many companies already use Enterprise Resource Planning (ERP) software. This helps them plan and manage their supply chain, finances, and other processes. However, PLM software for apparel has unique functionalities that work in tandem with enterprise systems.

You’ll want to find a PLM that integrates with your ERP if you’re already using one. Ideally, you’ll leverage the product data in your ERP to get the ball rolling with your PLM.

For a more comprehensive look at software tools, check out our PLM software blog.

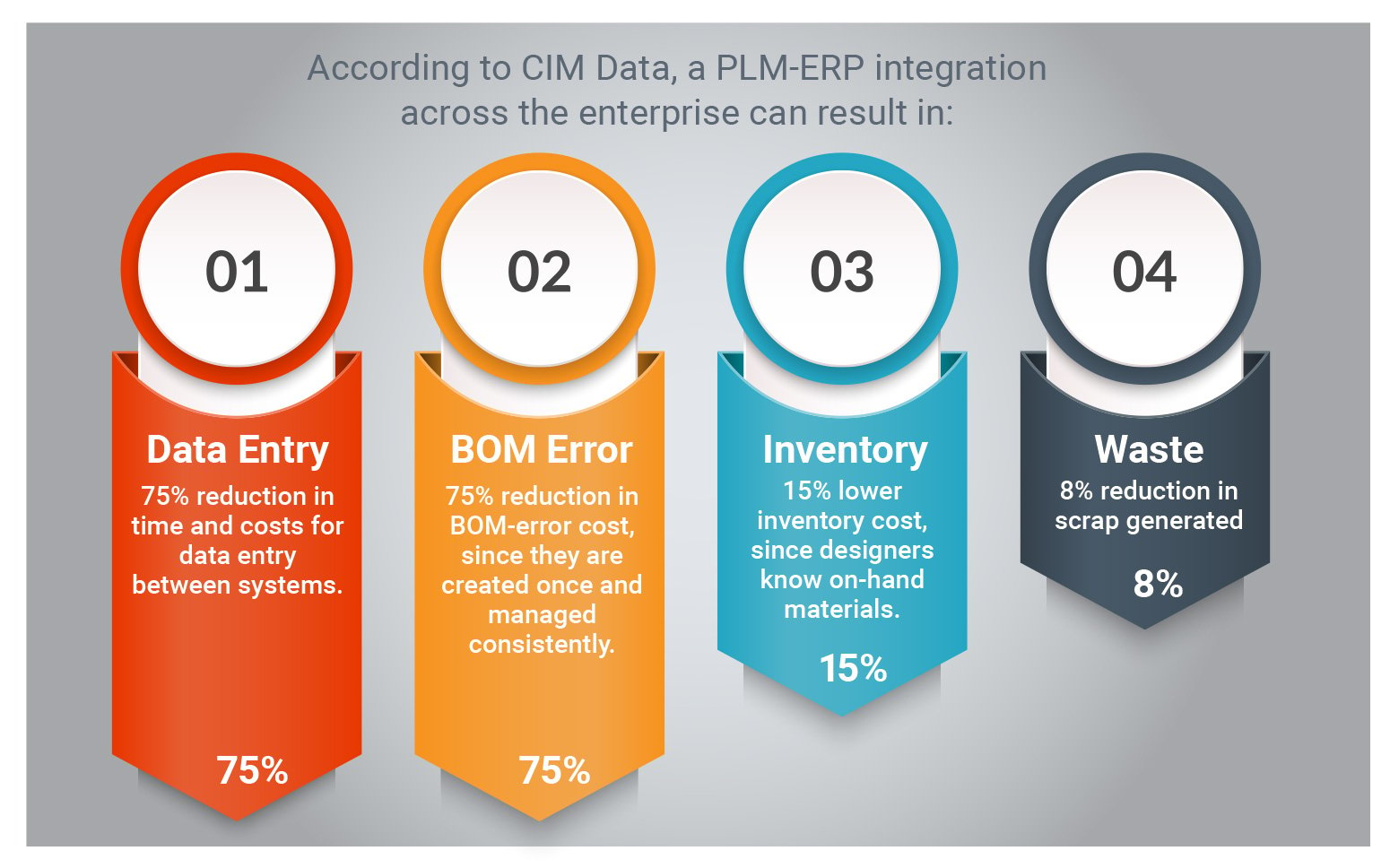

Recent industry data shows the benefits of PLM/ERP integration:

- 75% reduction in entering data from system to system (measure in relation to time, cost, and effort)

- 75% reduction in bill of materials (BOM) errors as BOMs are created once and managed across both the PLM and ERP systems.

- 15% reduction in inventory costs, since designers and product managers are aware of which materials are already on hand.

- 8% reduction in waste (scrap generated).

Why you should use Surefront for your fashion PLM

We recommend Surefront's Unified Product Collaboration Platform as an all-in-one solution for the fashion and apparel industry. Our retail PLM was designed with Product Information Management and Customer Relationship Management tools to reduce emails and data re-entry during product development.

Surefront takes a huge leap past traditional PLMs, arming the fashion industry with:

- Patented technology that allows your development team to engage with vendors and factories to complete products quickly and efficiently

- Access to in-depth product specifications, development histories, and images

- The ability to convert quotes to orders in seconds with our product syndication feature

- Tools for internal and external communication in one platform

- An end-to-end communication loop for all relevant parties

Our PLM gives you the agility and collaboration needed to push a product to completion. However, for your PLM to operate effectively, it needs to seamlessly integrate with your PIM and CRM tools.

You don’t want your data to be siloed. Your company’s CRM, PIM and PLM systems shouldn’t operate in a vacuum, either. Surefront is a Unified Product Collaboration Platform to power growth and ROI. Our patented PIM, CRM, and PLM solutions streamline the omni channel sales, merchandising and product development processes. By combining these essential functionalities, Surefront creates a single source of truth throughout your product lifecycle, sales and listing processes.

The results? Up to 150% more revenue per employee and a 40% shorter product development cycle is just the beginning. Try our 10x ROI calculator to see your company’s potential profits. Or, skip the noise and book a custom demo with one of our unified product collaboration management experts today. The retail industry evolves quickly and has a lot of moving parts. We do all of the research, so you don’t have to. Stay ahead of market fluctuations, trends and new features by subscribing to our Unified Product Collaboration Management Blog.

Share this

- PLM Software (36)

- PIM Software (29)

- Apparel & Fashion (20)

- Trending Topics (20)

- Merchandising (16)

- CRM Software (13)

- PLM Implementation (11)

- Catalog Management (6)

- Tech Packs (6)

- PLM RFP (5)

- Success Stories (5)

- Sustainability (5)

- Data Import (4)

- Line Sheet (4)

- Luxury Goods & Jewelry (4)

- Product Development (4)

- Retail (4)

- Supply Chain (4)

- Category Management (3)

- Home Furnishings (3)

- Wholesale (3)

- Consumer Packaged Goods (CPG) (2)

- Cosmetics (2)

- Data Export (2)

- Health & Beauty (2)

- RFQ & Quote Management (2)

- Consumer Electronics (1)

- Import & Export (1)

- Industry Events (1)

- Inventory Management (1)

- Pet Stores (1)

- Purchase Orders (1)

- Report Builder (1)

- Textiles & Raw Materials (1)

- Unified Solution (1)

- Vendor Management (1)

- Visual First (1)

- White Paper or Case Study (1)

- workflow (1)

- October 2025 (3)

- September 2025 (3)

- August 2025 (4)

- April 2025 (4)

- March 2025 (3)

- January 2025 (8)

- December 2024 (5)

- November 2024 (3)

- October 2024 (5)

- September 2024 (6)

- August 2024 (2)

- July 2024 (1)

- June 2024 (3)

- May 2024 (4)

- April 2024 (5)

- March 2024 (3)

- February 2024 (2)

- December 2023 (4)

- September 2023 (2)

- August 2023 (5)

- July 2023 (3)

- June 2023 (2)

- May 2023 (2)

- April 2023 (4)

- March 2023 (5)

- February 2023 (3)

- January 2023 (5)

- December 2022 (4)

- November 2022 (3)

- October 2022 (4)

- September 2022 (5)

- August 2022 (4)

- July 2022 (2)

- May 2022 (1)

- February 2022 (1)

- January 2022 (1)

- September 2021 (1)

- May 2021 (1)

- April 2021 (1)

- February 2021 (1)

- May 2020 (1)